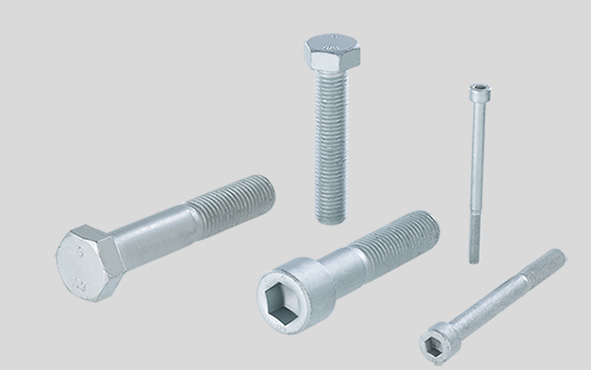

GEOMET® Coating

The chromium-free zinc-aluminium-flake system ensures that the coating is applied without any risk of hydrogen embrittlement even on fasteners.of high tensile strength because it is a non-electrolytic process. By the use of topcoats it is possible to adjust exactly the desired coefficient of friction on threaded parts.

GEOMET® inhouse coatings also on racks:

As acknowledged licensee and captive user GRAEWE Tadiv is now ready to provide the high level of corrosion protection for fasteners which is quaranteed by the GEOMET® trademark.

GEOMET® products are environment-friendly and safe in handling and application due to their unique waterbased technology. Not only for this reason GEOMET® is established since many years as worldwide standard for the coating of fasteners and many other metal parts.

This thin-layer corrosion protection is applied by GRAEWE Tadiv in an up-to-date coating-line which was specially designed to meet the requirements of threaded fasteners. The installation is capable of coating bulk parts as well as rack parts. Thereby sensitive parts can be coated without any damages. The need to rework threaded areas after the coating process and thus any negative impact on corrosion resistance is prevented by this flexible application technology.

The computerized coating process is continously monitored, the defined coating thickness is checked regularly and the corrosion resistance frequently verified by salt spray testing. Furthermore the coefficient of friction can also be measured on-site.

GRAEWE Tadiv is acknowledged licensee for the chrome-free coating technology GEOMET® provided by NOF Metal Coatings Europe S.A. and certified by TÜV Süd according to DIN EN ISO 9001:2008. GRAEWE is also meeting the demands of the german "AD-Merkblatt W0/TRD".